👤 Rockshell Insights

18/11/2025

India is one of the fastest-growing industrial economies in the world, with chemical processing, pharmaceuticals, food & beverage, and manufacturing sectors expanding rapidly. But with this growth comes an unavoidable challenge energy consumption.

Industrial heating and cooling alone account for over 50% of energy use in many chemical plants. Traditionally, this demand has been met by coal-fired boilers, oil burners, or gas-based systems, which are not only costly but also carbon-intensive.

As India pushes forward with its net-zero targets for 2070, industries are under pressure to adopt sustainable and efficient technologies. Enter heat pumps – a solution that recycles waste heat, reduces emissions, and delivers unmatched efficiency.

In this blog, we’ll explore why India urgently needs industrial heat pumps, how they can revolutionize heating and cooling systems, and what sustainability trends are shaping their adoption.

What Are Industrial Heat Pumps?

An industrial heat pump is a system that transfers and upgrades heat from one source (like waste heat or ambient energy) to another, using a refrigeration cycle. Unlike boilers that burn fuel, heat pumps reuse existing energy to deliver heat or cooling.

Key Features of Industrial Heat Pumps:

- High operating temperatures (up to 160°C depending on the design).

- Ability to handle aggressive fluids like alkaline or acidic solutions.

- High Coefficient of Performance (COP) typically 3 to 6.

- Applications across evaporation, drying, distillation, and Zero Liquid Discharge (ZLD) systems.

In short: they save energy, cut emissions, and deliver reliable process heating & cooling.

The Energy Landscape in India

India’s energy needs are massive, and industries are the largest consumers:

- Coal dependency: Nearly 70% of India’s electricity is still coal-based.

- Rising fuel costs: Oil and gas imports increase financial burdens.

- Carbon emissions: India is the third-largest emitter of CO₂ globally.

- Government regulations: Strict policies are being introduced to reduce industrial pollution.

For industries, the message is clear fossil fuel dependency is no longer sustainable. The solution lies in technologies like industrial heat pumps that align with both economic and environmental goals.

Why Heat Pumps Are a Game-Changer for Indian Industries

- Energy Efficiency and Cost Savings

Heat pumps recover waste heat from exhaust gases, wastewater, or process vapours, and reuse it. This dramatically reduces the need for external fuel.

- Boilers: ~80–90% efficiency.

- Heat Pumps: COP of 3–6 (300–600% efficiency).

This means Indian industries can cut operating costs by 40–60%, a huge advantage in energy-intensive sectors.

- Sustainability and Carbon Reduction

With India’s carbon neutrality pledge, industries are under pressure to adopt low-carbon technologies. Heat pumps, powered by electricity (increasingly sourced from renewables like solar/wind), can slash emissions.

- Less coal = cleaner air.

- Lower CO₂ footprint = stronger ESG scores.

- Better compliance with global buyers demanding sustainable supply chains.

- Versatility in Applications

Heat pumps aren’t limited to space heating or cooling. In India, they can transform critical industrial processes:

- Chemical Industry: Concentrating, distilling, or drying chemical solutions.

- Food & Beverage: Pasteurization, drying, brewing, cold storage.

- Pharmaceuticals: Maintaining precise heating/cooling cycles.

- Textiles & Paper: Efficient drying and steam generation.

- Water & Wastewater: Enabling Zero Liquid Discharge (ZLD) and recycling.

- Support for Renewable Integration

India is rapidly scaling up solar and wind energy. Heat pumps run on electricity, making them ideal partners for renewable integration. They allow industries to shift away from fossil fuels while using cleaner electricity sources.

- Government Push and Incentives

The Indian government is incentivizing industries to adopt energy-efficient technologies under schemes like:

- PAT (Perform, Achieve and Trade) by Bureau of Energy Efficiency (BEE).

- National Mission on Enhanced Energy Efficiency (NMEEE).

- Local subsidies for waste heat recovery and renewable integration.

Adopting heat pumps helps industries comply with these frameworks while reducing energy costs.

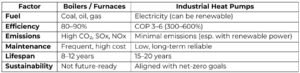

Heat Pumps vs. Conventional Industrial Heating Systems

Clearly, heat pumps are the future-proof alternative for India’s industrial sector.

Trends Driving Heat Pump Adoption in India

- Decarbonization Pressure

Industries are being pushed by governments, global buyers, and ESG standards to reduce their carbon footprints. Heat pumps are a direct enabler.

- Energy Cost Volatility

With fluctuating global oil and gas prices, industries are seeking stable, predictable cost structures. Heat pumps powered by electricity provide that stability.

- Circular Economy & Waste Heat Recovery

India’s industrial clusters generate massive waste heat. Capturing and reusing it through heat pumps is becoming a mainstream efficiency strategy.

- Digitalization & Smart Manufacturing

Modern heat pumps integrate with IoT and automation systems, enabling predictive maintenance, energy monitoring, and real-time optimization.

- Local Manufacturing Push

With initiatives like Make in India, manufacturers like Rockshell Corp are producing advanced heat pump systems locally, reducing costs and increasing adoption rates.

Real-World Example for Heat Pump

A chemical processing unit in Gujarat replaced coal-fired boilers with high-temperature industrial heat pumps. The results:

- Energy cost savings: 48% reduction.

- CO₂ reduction: Over 2,000 tonnes annually.

- Water savings: Integrated with ZLD for efficient wastewater treatment.

- Payback period: 3 years.

Such case studies prove that heat pumps are not just theoretical solutions they deliver practical results for Indian industries.

Rockshell Corp: Driving the Heat Pump Revolution in India

At Rockshell Corp, we design and manufacture industrial heat pumps tailored for India’s challenging industrial landscape. Our solutions are:

- Built with corrosion-resistant alloys to handle acidic and alkaline chemicals.

- Engineered for high COP and long-term energy efficiency.

- Compatible with applications like ZLD systems, high-temperature chillers, and evaporators.

- Manufactured in India, ensuring global quality with local expertise.

By choosing Rockshell, industries gain a trusted partner in their transition to sustainable and efficient energy use.

👉 Explore Rockshell’s Heat Pump Solutions

Conclusion: The Time Is Now

India’s industrial future will be shaped by technologies that balance growth with sustainability. Heat pumps are no longer just an option they are a necessity for industries seeking:

- Lower energy bills

- Reduced emissions

- Compliance with sustainability norms

- Future readiness in a carbon-constrained world

By embracing industrial heat pumps today, Indian industries can lead the way in building a cleaner, more efficient tomorrow.